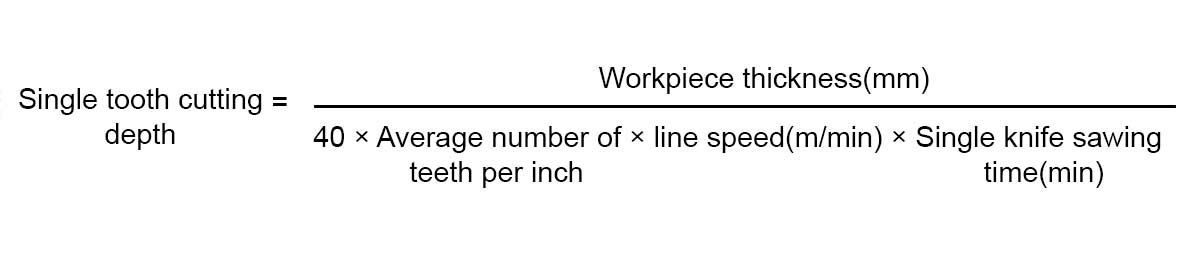

(1) single-tooth cutting depth judgment method.

Common materials single tooth cutting depth range | |

Aluminum, copper alloy 0.008~0012mm | Die steel 0.002~0.0035mm |

Carbon steel 0.005~0.009mm | 304/316 Stainless steel 0.0015~0.003mm |

Alloy structural steel 0.004~0 007mm| | Titanium alloy 0.0025~ 0.0035mm |

Tool steel 0.0035~0.005mm | High temperature alloy 0.001~0.0015mm |

The cutting depth of a single tooth can be changed by the change of line speed, tooth pitch and cutting time. The cutting depth of a single tooth with the right cutting depth can avoid the early edge breakage wear of the tooth tip.

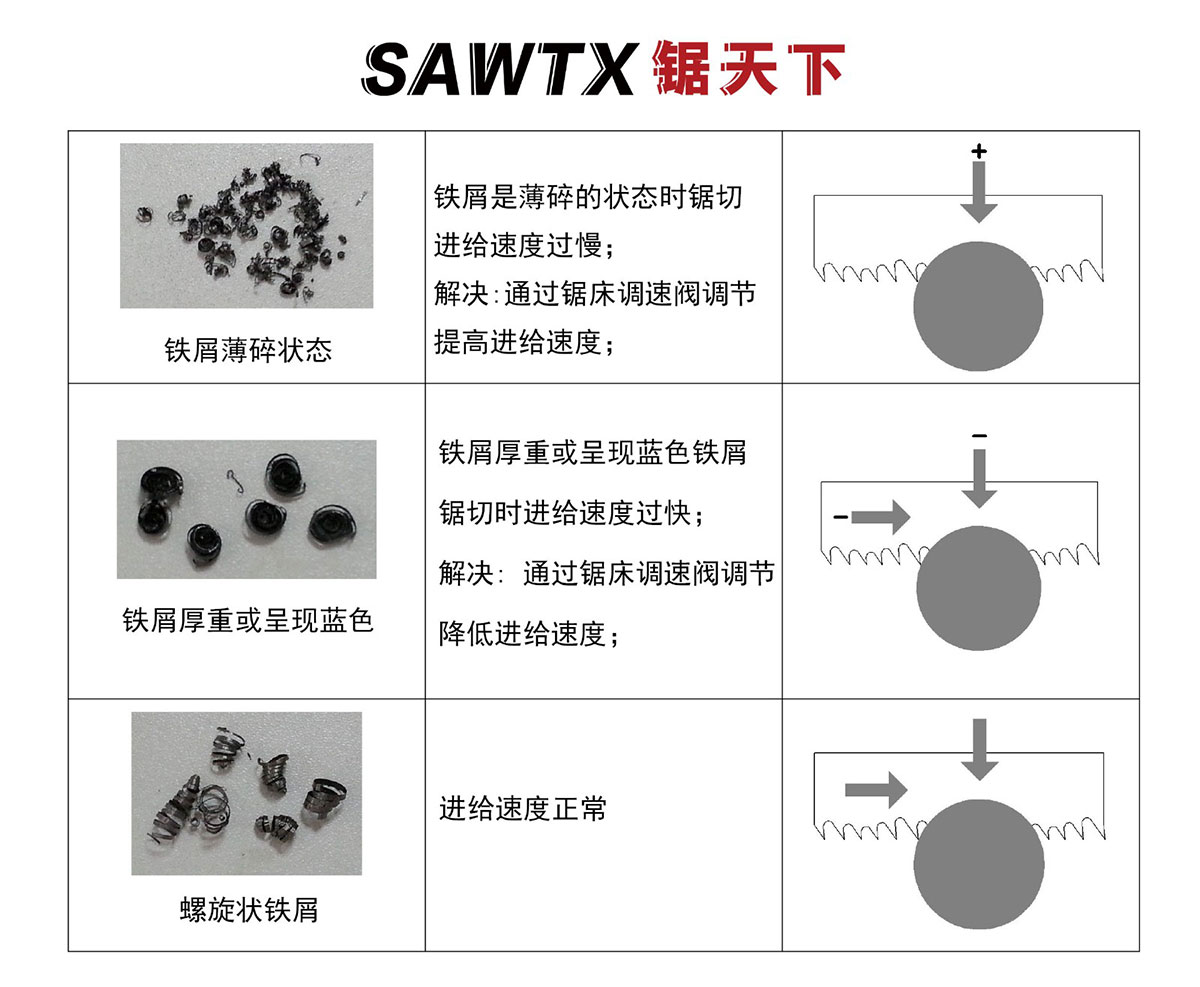

(2) Chip status judgment method:

In the field sawing, the rationality of the parameters can be judged by observing the shape, elasticity, color and temperature of the chips (see the following table).

Your location:

Your location:

Home

Home Consult

Consult Products

Products