Our company high-speed band sawing machine product introduction

Our company introduced German technology series production of high-speed band sawing machine, using different configurations, can be used for high-speed cutting of the following high-end materials:

1. High-speed cutting of non-ferrous metal materials, such as aluminum plate, aluminum casting gate, engine housing, honeycomb aluminum, foamed aluminum, aluminum ingots, industrial aluminum profiles, aluminum bars and aluminum pipes;

2. High speed cutting of wear-resistant materials, such as graphite, cathode carbon block, carbon fiber, wear-resistant ceramics, brake pads, foamed cement, etc.

3. High-speed cutting of crystal materials, such as glass, quartz, monocrystalline silicon, polysilicon, precious stones, semiconductor materials, etc.

High speed band sawing machine has high cutting efficiency, smooth surface, good precision and high safety, which has been applied in many manufacturers, and has played a role in replacing imports, improving efficiency, saving energy and reducing consumption, and has created benefits for users.

User requirements

Cutting aluminum ingot: trapezoidal section upper bottom * bottom * height =100*180*100 mm, length 800 mm, sawed into 5 sections.

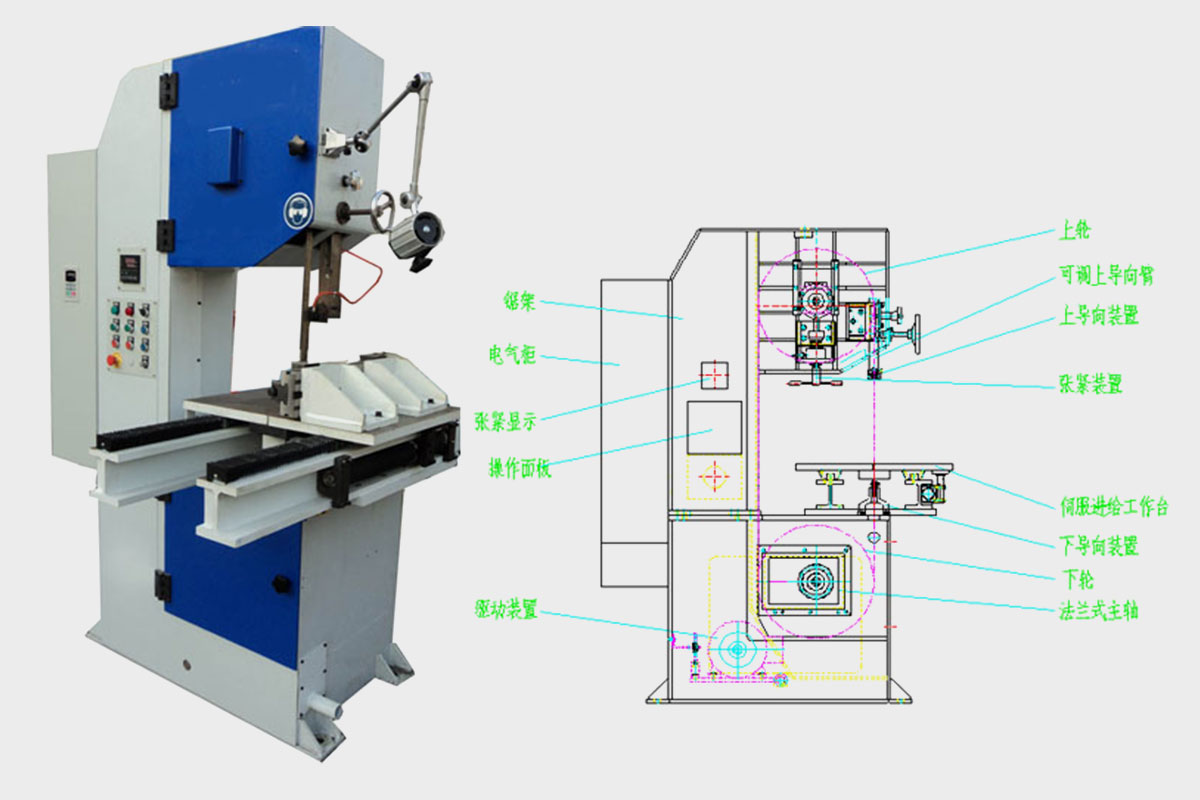

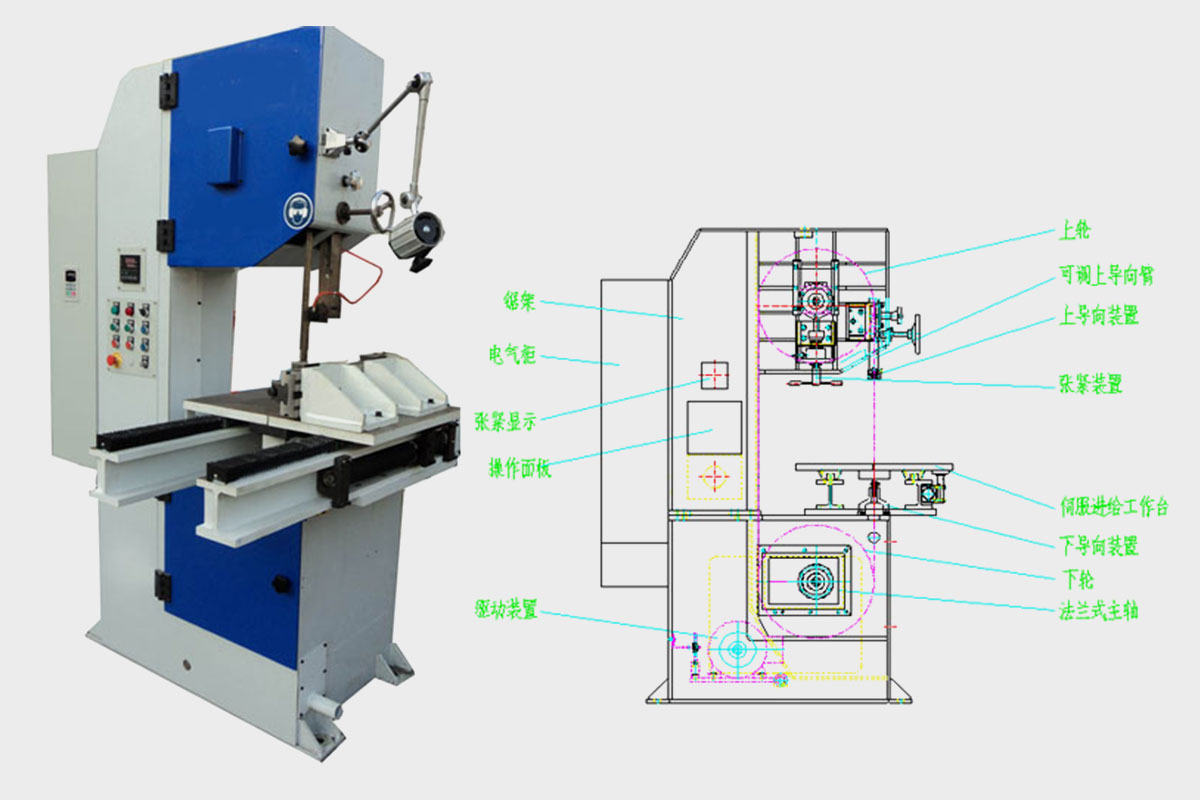

GG520 high-speed vertical band sawing machine reference photos and structural sketch

GG520 high-speed vertical band sawing machine composition and characteristics

1. Stable group welding saw frame, finishing after aging, enhance the stability of high-speed operation;

2. The band line speed can be adjusted by frequency conversion, the adjustment range is large, suitable for high-speed sawing of different aluminum and aluminum alloy materials;

3. Saw band manual tensioning device; The tension force digital display device can be purchased, and the upper wheel broken belt brake can also be purchased, which is safer.

4. Roller or clip type precision saw belt guide device;

5. Upper guide arm adjustable up and down, manual mechanical.

6. Aluminum alloy pulley, surface vulcanized hard rubber, high speed and stable operation;

7. Open door power off design to ensure safety;

8. Servo motor feed table, speed stepless adjustment, work table can design simple workpiece positioning equipment.

9. Compressed air cooling purge device with pressure regulator and electromagnetic switch, compressed air supplied by the user.

10. Saw band spray lubrication device with industrial alcohol and water. Compressed air is provided by the user. Imported spray lubrication device can be purchased, the use of imported plant lubricating oil, less consumption, degradable, used for non-ferrous metal and its alloy sawing use, extend the service life of the saw belt.

GG520 high-speed vertical band sawing machine main technical parameters

1. Wheel diameter: 520 mm

2. Saw belt speed: 500~1800 m/min variable frequency adjustable

3. Throat depth: 500 mm

4. Throat height: 320 mm

5. Saw belt motor: 5.5 kW

6. Table servo motor: 0.5 kW

7. Saw belt specification: 4160*27*0.9 mm

8. Feed table size: front and back 550 mm, about 900 mm (saw belt left and right)

9. Feed table stroke: 400 mm

10. Weight: About 1100 kg

Cutting process

1. Work table quickly back to the front;

2. Set the tool according to the cutting size and locate the workpiece; Two aluminum ingots can be placed at the same time

3. Fast forward the table to the cutting position;

4. Adjust the cutting speed and feed speed;

5. Start the saw belt, and the saw belt starts to run;

6. Table feed start, start cutting;

7. After cutting, the table feed stops;

Main purchased parts

1. Inverter: Delta, panel speed regulation

2. Servo motor speed control: Delta motor and controller are selected

3. Guide rail and lead screw: Taiwan brand

4. Bearing: Harbin bearing

5. Main motor: Siemens Bader motor

4. One year warranty period, pay 5% balance.

Quality Guarantee period

One year after delivery

Your location:

Your location:

Home

Home Consult

Consult Products

Products