1. Main technical parameters:

| Sawing machine model | V6-GZK4025 |

| Sawing ability (mm) | Φ250□165×250 (Excluding compression) |

| Blade specifications (length x width x thickness) (mm) | 3505×27×0.9 |

| Saw blade line speed (m/min) | Five types: 27, 40, 54, 68, and 80 |

| Main motor power (Kw) | 2.2kw/Level 4 |

| Hydraulic pump power (Kw) | 0.75 |

| Cooling pump power (kw) | 0.04 |

| Sawing feed rate | Hydraulic infinite speed regulation |

| Blade tensioning method | Manual tensioning, spring protection |

| Workpiece clamping method | Hydraulic vice |

| Feed length | Manual: 0.1-9999 Automatic: 0.1-9000 |

| Number of delivered items | 0-900 |

| One feeding length (mm) | 400 |

| Sawing machine size (mm) | 1800*2100*1400 |

| Sawing machine weight (KG) | 1300 |

2. Basic characteristics of sawing machine

Suitable for large quantities of repetitive blanking. Using CPU control, one setting, can automatically complete 1-999 from the delivery to the finished product automatic working process.

Operation mode: Manual/automatic.

The control system uses CPU microcomputer control (screen display, can input up to 32 groups of cutting data at one time), non-market PLC (button control), higher automation, more stable system.

The saw blade guide device combined with rolling bearing and carbide saves the loss of band saw blade.

Hydraulic feeding, a feeding length of 400mm, can be reciprocated feeding. The length can be selected according to user requirements.

The band saw blade quickly approaches the workpiece and automatically switches to the cutting speed, the lifting saw height is automatically adjusted with the size of the workpiece, and a lot of empty time can be saved in the automatic cycle process.

Automatically count and display the number of sawing segments and feeding length.

The length is set by setting the position of the size stop of the feeding mechanism, and the position of the size stop is precisely displayed by the digital position display.

Using grating ruler positioning, positioning accuracy is high, workpiece error is less than 0.1mm.

With saw blade broken belt shutdown and other safety protection, safer operation, to avoid operator accidents.

3. Working process

After manual feeding, set the cutting length and the number of knives in the automatic state. Press the running button, back clamp loose (2 seconds) → cylinder back → Back clamp, front clamp loose (2 seconds) → cylinder feed (12 seconds /400mm can be achieved by one or more feeding length) → Front clamp, back clamp loose (2 seconds) → work sawing (stepless speed regulation, about 35-55mm/ min according to 45# steel feed), cylinder back → lift saw (12 seconds /250mm) → Next cycle to complete the set tool number machine stop.

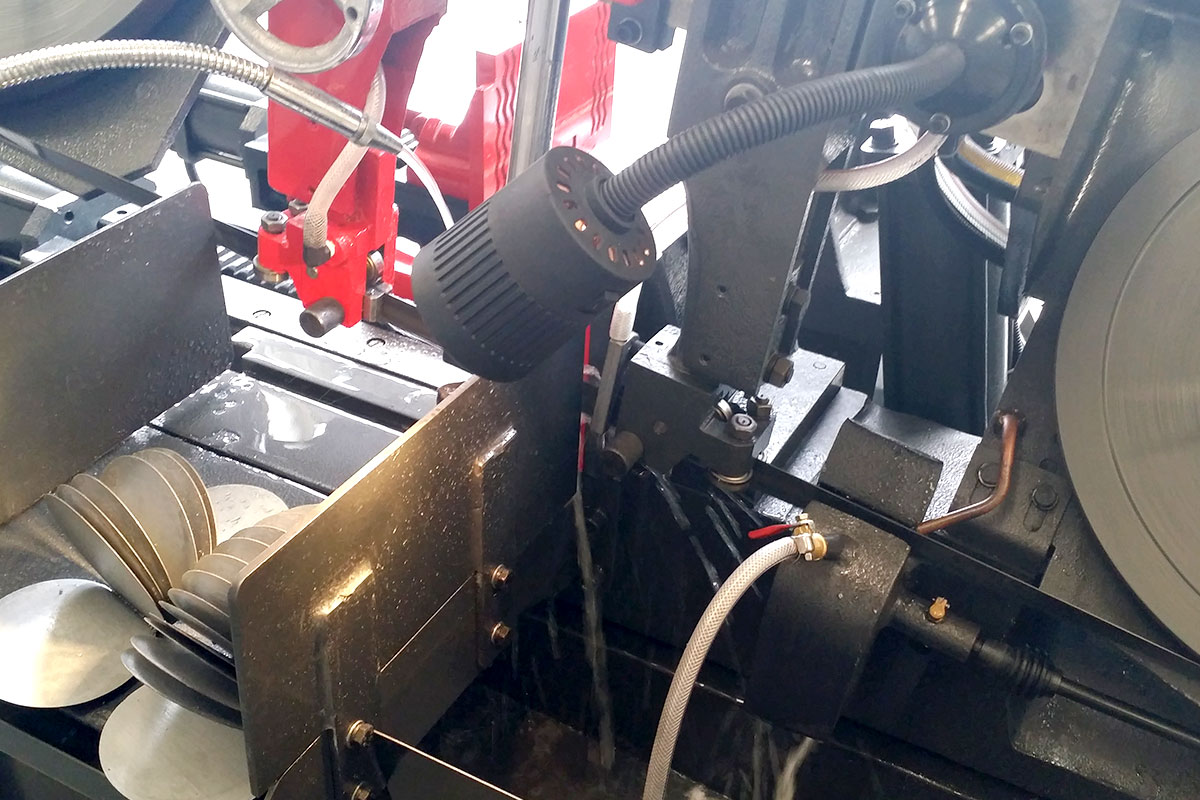

Customer application site

Your location:

Your location:

Home

Home Consult

Consult Products

Products