1. Main technical parameters:

| Sawing machine type | V6-GZK4250 |

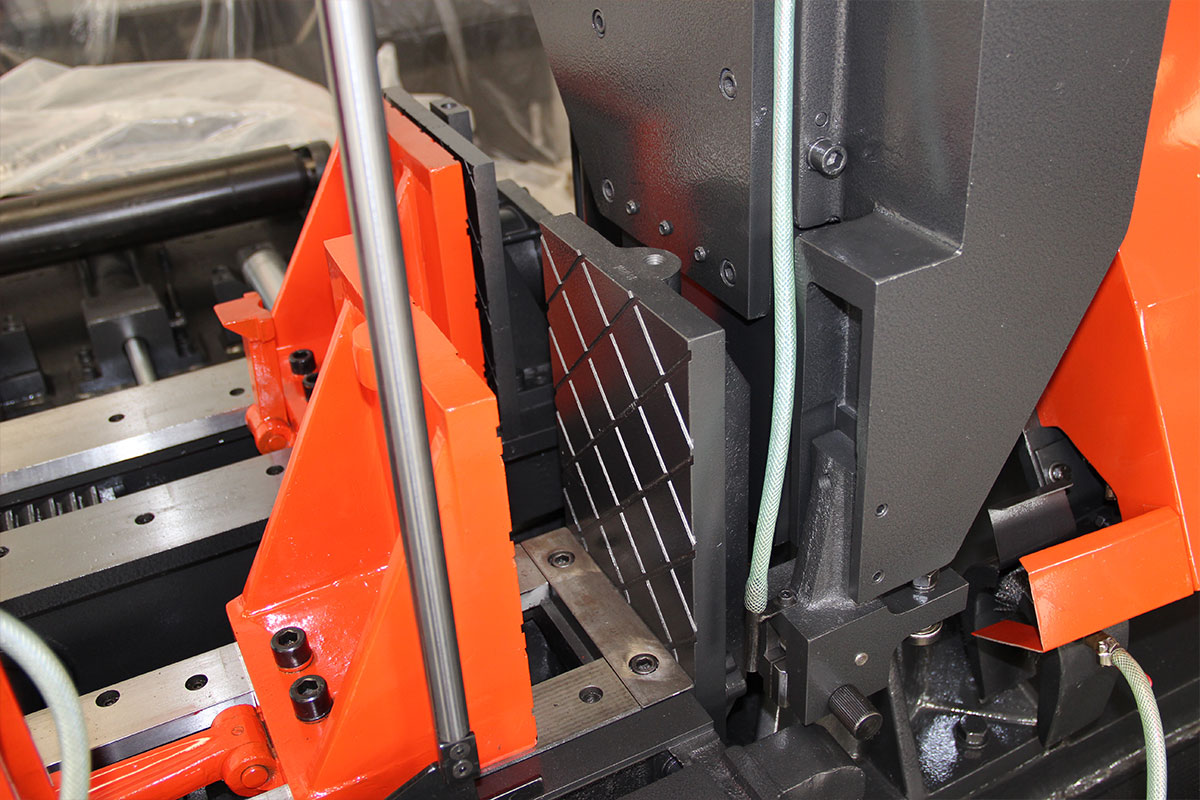

| Cutting capacity (mm) | Φ500□500H×500W(without top pressing) |

| Saw band specification (L × W × T) (mm) | 5500×41×1.3 |

| Band sawing speed (m/min) | 28、48、70 (Driven wheel sensor count, computer display) |

| Main motor Power (KW) | Saw belt main drive: 4KW-6 hydraulic drive: 1.5KW-4 |

| Feeding length (mm) | Larger 500 |

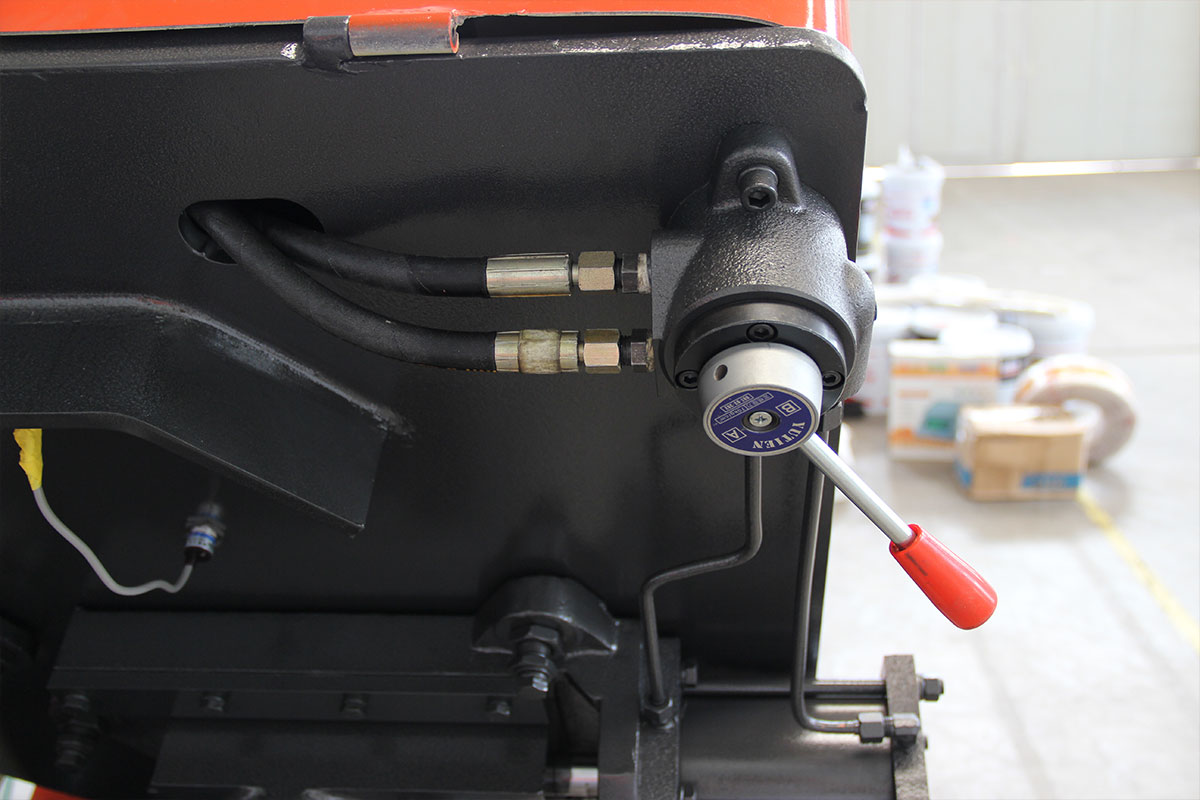

| Feed speed (m/min) | Hydraulic speed control |

| Saw band tension type | Hydraulic tensioning |

| Band correction | Hydraulic compaction |

| Hydraulic tank volume | 48 liters |

| Cutting fluid tank volume | 80 liters |

| Table height (mm) | 600mm |

| Allowable load (KG) | 3500KG |

| Overall dimensions (L × W × H) (mm) | 2800×2500×2000 |

| Weight (Kg) | 2800 |

2. Main technical description

a) Suitable for large quantities of repetitive cutting. Using CPU (microcomputer) control, one setting, can automatically complete 1-999 from the delivery to the finished product automatic working process.

b) Operation mode: manual/automatic.

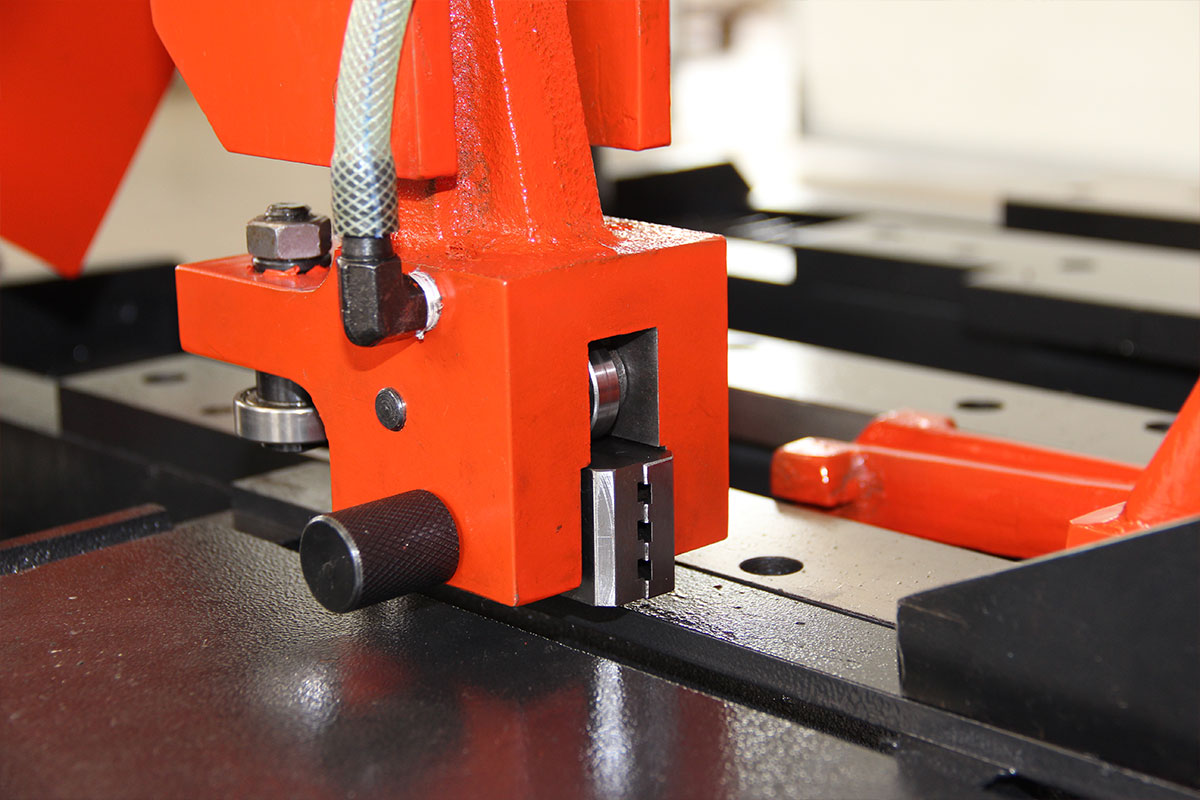

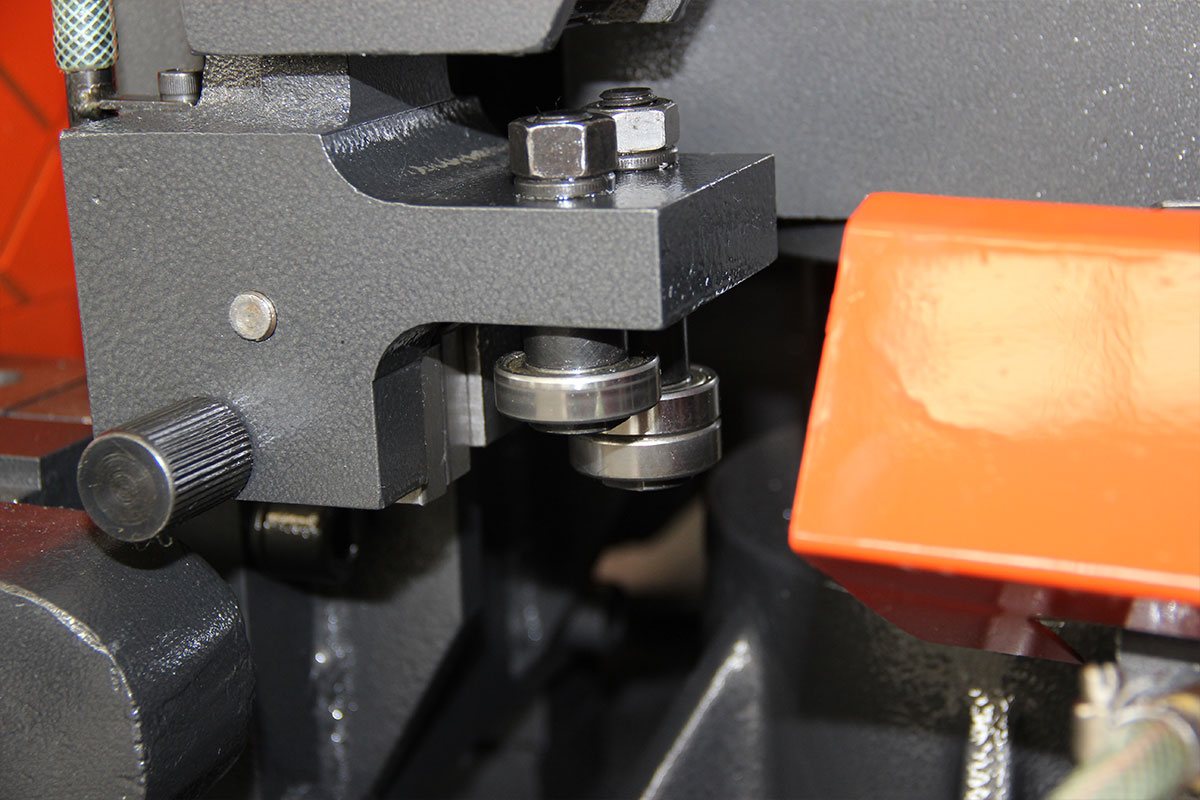

c) Saw blade guide device with combination of rolling bearing and carbide.

d) Hydraulic feeding, feeding length can be selected according to user requirements, within 500mm optional.

e) The band saw blade quickly approaches the workpiece and automatically switches to the cutting speed, the lifting saw height is automatically adjusted with the size of the workpiece, and a lot of empty time can be saved in the automatic cycle process.

f) Automatically count and display the number of sawing segments and feeding length.

g) The length is set by setting the position of the size stop of the feeding mechanism, which is precisely displayed by the digital position display.

3. Working process

After manual feeding, set the cutting length and the number of knives in the automatic state. Press the running button, back clamp loose → cylinder back → Back clamp, front clamp loose → cylinder feed (the length can be determined by one or more feeding) → Front clamp, back clamp loose → work sawing (stepless speed regulation, about 35-55mm/ min according to 45# steel feed), cylinder back → lifting saw → next cycle until the set number of tools is completed.

4. Service commitment:

a) Understand the production and processing needs of users before sales, provide users with band sawing machine products with reasonable performance and price, provide timely and accurate technical help to users when necessary, and make necessary explanations on technical documents, drawings, instructions for use, equipment performance, analysis methods, etc.;

b) Train operators and maintenance personnel on equipment operation, maintenance, analysis and inspection after product delivery;

c) If the product fails during use, reply in time after receiving the user's maintenance notice or send service personnel within 24 hours;

d) To ensure long-term provision of maintenance spare parts for outgoing products.

5. Ordering Instructions:

a) By default, the sawing machine does not include the upper clamping set (clamping device for bundle cutting), which can be purchased separately on request.

b) If the actual cutting range will be smaller after ordering the upper pressing device, please communicate with the sales staff in advance according to the actual use.

c) The installation and commissioning of free equipment is only limited to the surrounding areas of Hebei, and some fees will be charged for commissioning in other areas. The specific fees will be negotiated depending on the distance.

Your location:

Your location:

Home

Home Consult

Consult Products

Products