I. Key Technical Parameters

| Sawing machine model | GZK4235 |

| Sawing capacity (mm) (without upper clamping sleeve) | Round stock:○350 Square stock:□350×350 |

| Saw band spec. (length× width× thickness) mm | 4250×34×1.1 |

| Saw band speed(m/ min) | 22、32、43、55、65 |

| Main motor power(kw) | 3.0 kw |

| Hydraulic pump power(kw) | 1.5 |

| Cooling pump power(kw) | 0.04 |

| Feeding length | 500 mm |

| Number of feeding parts | 0-999 Root |

| Number of groups | 1-8 Groups |

| Saw band wheel diameter | ○500 mm |

| Work bench height | 710 mm |

| Motor:Saw band main drive | 3.0KW、6 Level |

| Motor:Hydraulic transmission | 0.75KW、4 Level |

| Hydraulic oil tank volume | 18 L |

| Cutting fluid tank volume | 40 L |

| Cutting fluid pump | Water pump DB-12A |

| Power | 40W 380V |

| Allowable load weight | 1700 kg |

| Machine weight | 1500 kg |

| Feed speed | Hydraulic control (none) |

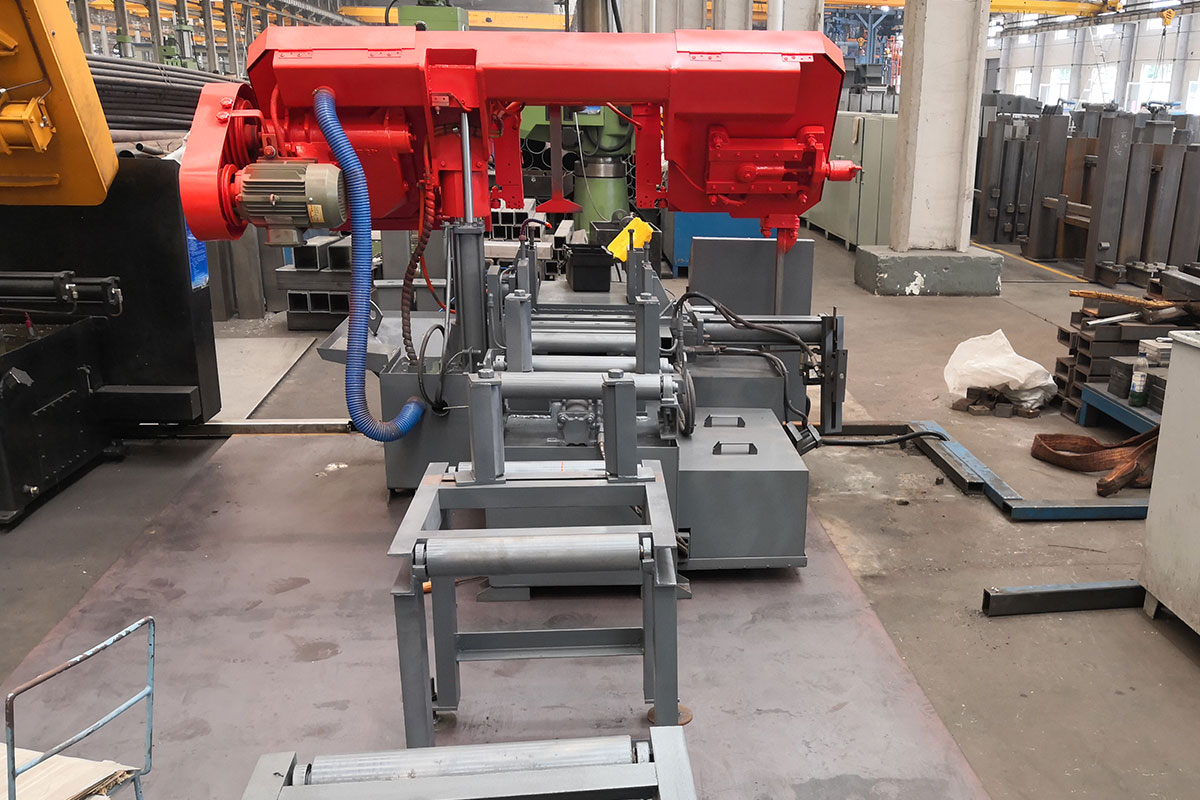

| Outline dimensions of machine(length× width× thickness) mm | 2200×2300×1650 |

| Machine weight(kg) | 2800 |

II. Main Purpose

This machine tool is primarily used for sawing various steels, such as difficult-to-cut materials, special alloy steels, high-alloy steels, low-alloy steels and mild steels. The product can cut non-ferrous and non-metallic metals with different saw blades.

III. Performance Features

1. The CPU microcomputer automatic control system is used to set the automatic program of the whole sawing process, and manual operation can also be selected.

2. The man-machine interface displays the operation status, parameter setting, and operation instructions of the equipment for simple and efficient operation.

3. The operation instructions are built-in, and the sawing data statistics is made background, simple, clear and convenient.

4. The sawing length, number of groups and quantity can be set in a variety of ways, and they are displayed in real time. The feeding length is controlled by the magnetic railing ruler, and the length error is less than 0.2mm.

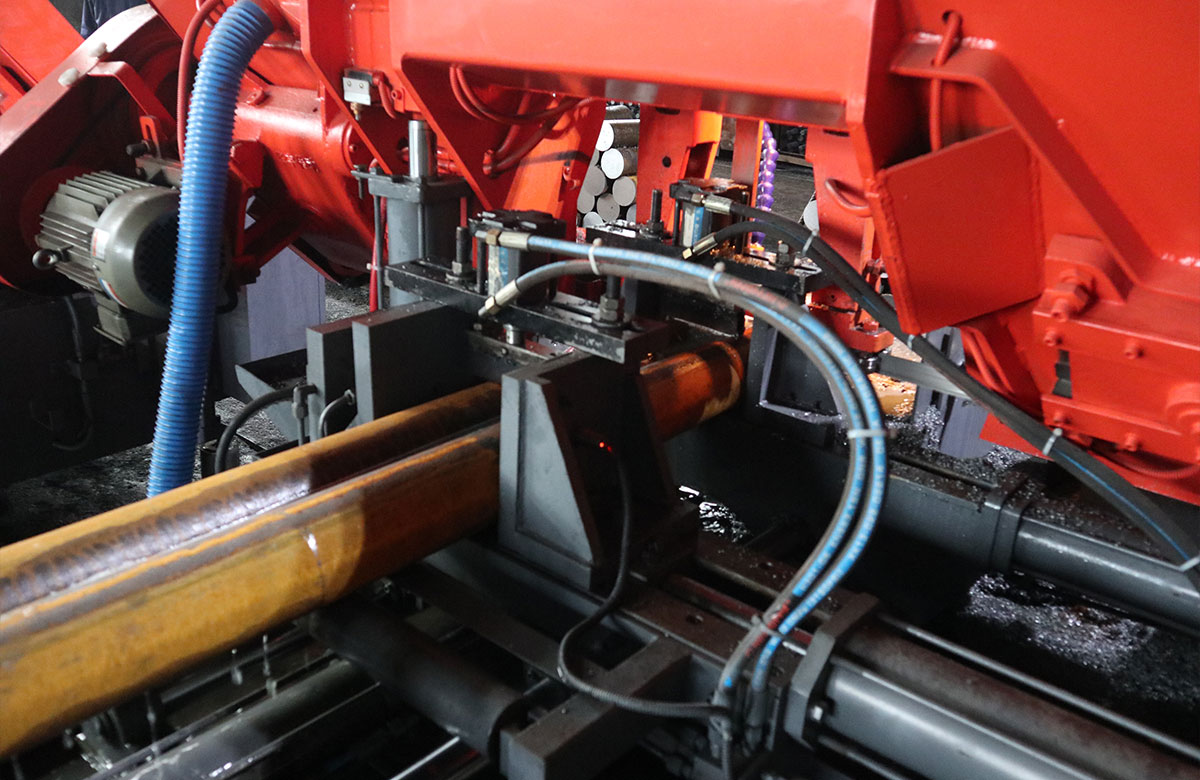

5. The hydraulic clamping of the workpiece and the hydraulic feed mode are optional, and the sawing speed is regulated hydraulically and steplessly.

6. The saw band is flexibly tensioned to prolong the service life of the saw blade. The structure is reasonable, the machine bed is heavy, the saw frame is stable, the performance is stable and reliable, and the precision is high.

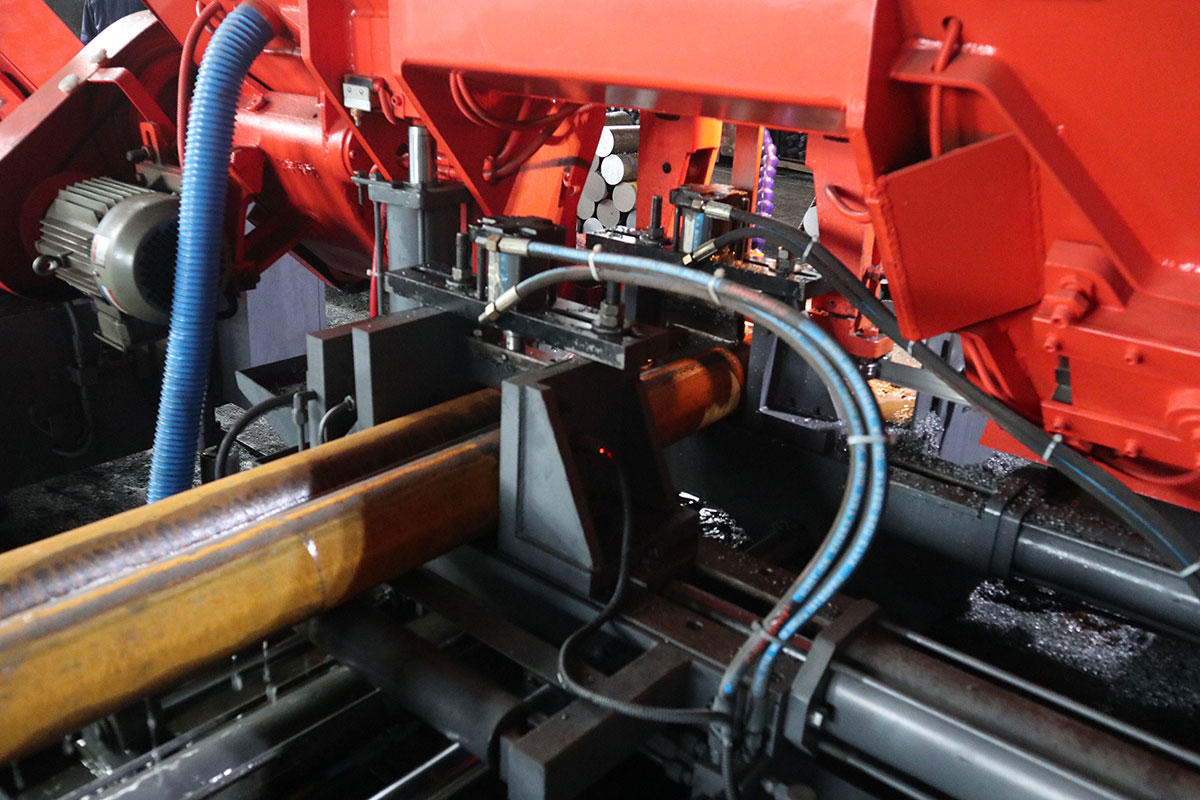

7. The saw blade adopts the active mechanism of steel brush for chip removal. With water flushing, the chips can be removed completely and the service life of the saw bland is prolonged.

8. The saw blade guide structure is scientific and reasonable, and the rolling bearings and cemented carbide block guides are used to save saw blades and ensure high sawing accuracy.

9. Bundle sawing device – Upper clamp (optional)

IV. Ordering Notice

a) The sawing machine has no the upper clamping device (clamping device used for bundle cutting) by default, and it can be purchased separately if required;

b) If the actual cutting range will be smaller after ordering the upper clamping device, please contact the sales personnel in advance according to the actual situations;

c) The installation and commissioning of the equipment free of charge are available only for the surrounding areas of Hebei, and some cost will be paid for commissioning in other areas; the special cost will be determined through negotiation depending on the distance.

Home

Home Consult

Consult Products

Products