I. Key Parameters of Machine Tools

| Sawing range | Round stock 250mm Square stock 280×250mm |

| Saw band spec.(length×width×thickness) | 3505×27×0.9mm |

| Saw band wheel diameter | f400mm |

| Saw band running speed | 27、40、54、68、80(m/min) |

| Saw band feed speed | Hydraulic stepless regulation, Auto fast feed converted to workpiece feed |

| Saw band motor | 2.2KW |

| Hydraulic motor | 0.55KW |

| Cooling pump | 0.04KW |

| Supply voltage | 380V,50Hz |

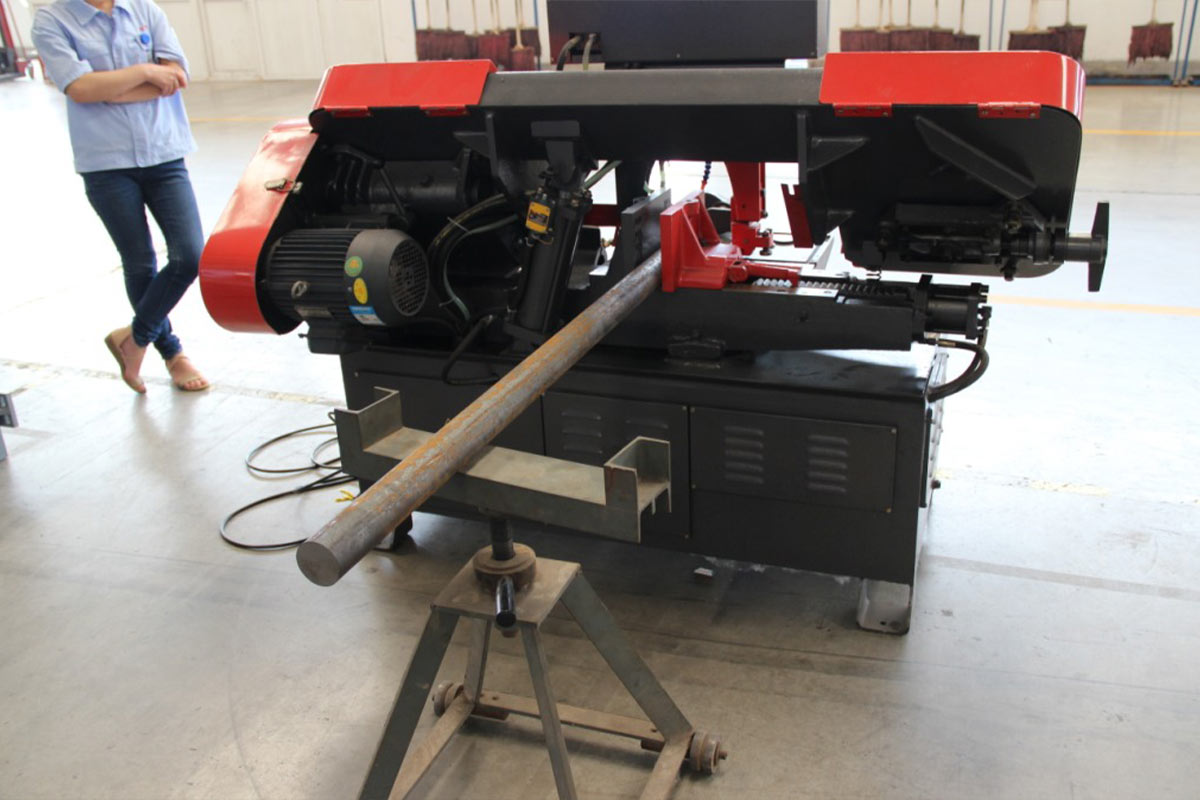

| Machine outline dimensions(L×W×H) | 1900×1180×1220mm |

II. Accuracy

A. Verticality of sawing surface mm: 0.20/100

B. Repeated positioning accuracy of the length mm: 0.30

III. Basic Features and Configuration of the Machine Tool

A. Machine structure: Horizontal semi-automatic.

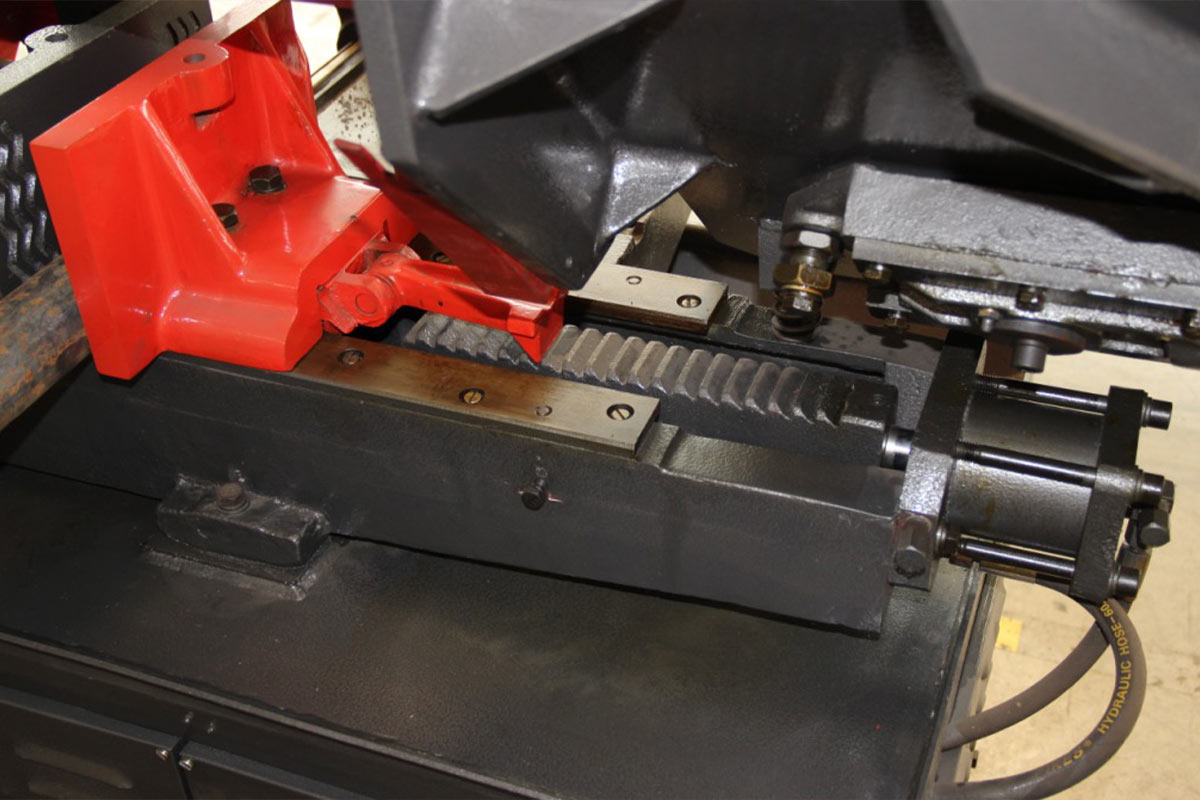

B. The upper, lower, left and right hydraulic tightening actions can be realized, and sawing the bundles is also available. (The upper clamping device is not in the standard configuration, and it shall be purchased separately according to the users’ needs).

C. Operation method: Manual / Auto; buttons are used to ensure convenient and simple operations.

D. The use of saw bland guide device composed of the rolling bearing, the cemented carbide, and the spring positioning system can prolong the service life of the saw blade.

E. Saw blade feed speed, with hydraulic stepless speed regulation.

F. A closed large fuel tank is used to ensure continuous operations for 24 hours without generating heat.

G. Worm gear drive.

H. Machine feeding rack and carriage.

I. Recovery to high accuracy by adjustment after long-time operation.

J. All structural parts are subject to the vibration aging treatment to eliminate residual stress to a maximum extent and prevent the deformation of the machine tool.

K. The parts are subject to the shot blasting treatment to enhance the adhesion of the paint film and increase the strength and rigidity of the machine tool.

IV. Service Commitment

a) Our company will understand the user’s production and processing needs before sales to provide users with band sawing machines with reasonable performance and price, and will go to the user’s site to provide timely and accurate technical assistance to the user when necessary and make reasonable explanations on technical documents, drawings, use instructions, equipment performance, and analysis methods.

b) After the product is delivered, perform the training about equipment operation, maintenance and analysis and inspection for operators and maintenance personnel;

c) If found fault during the operation of the product, a timely reply is made or the service personnel will be dispatched within 24h after receiving the maintenance notice issued from the user;

d) It is ensured that spare parts for maintenance are provided for delivered products.

V. Ordering Notice

a) The sawing machine has no the upper clamping sets (the clamping device used for bundle cutting) by default, and it can be purchased separately if required.

b) If the actual cutting range is smaller after the upper clamping device is purchased, please contact the sales personnel in advance according to the actual use situations.

c) The installation and commissioning of the equipment free of charge are available only for the surrounding areas of Hebei, and some cost will be paid for commissioning in other areas; the special cost will be determined through negotiation depending on the distance.

Home

Home Consult

Consult Products

Products