I. Main Purpose

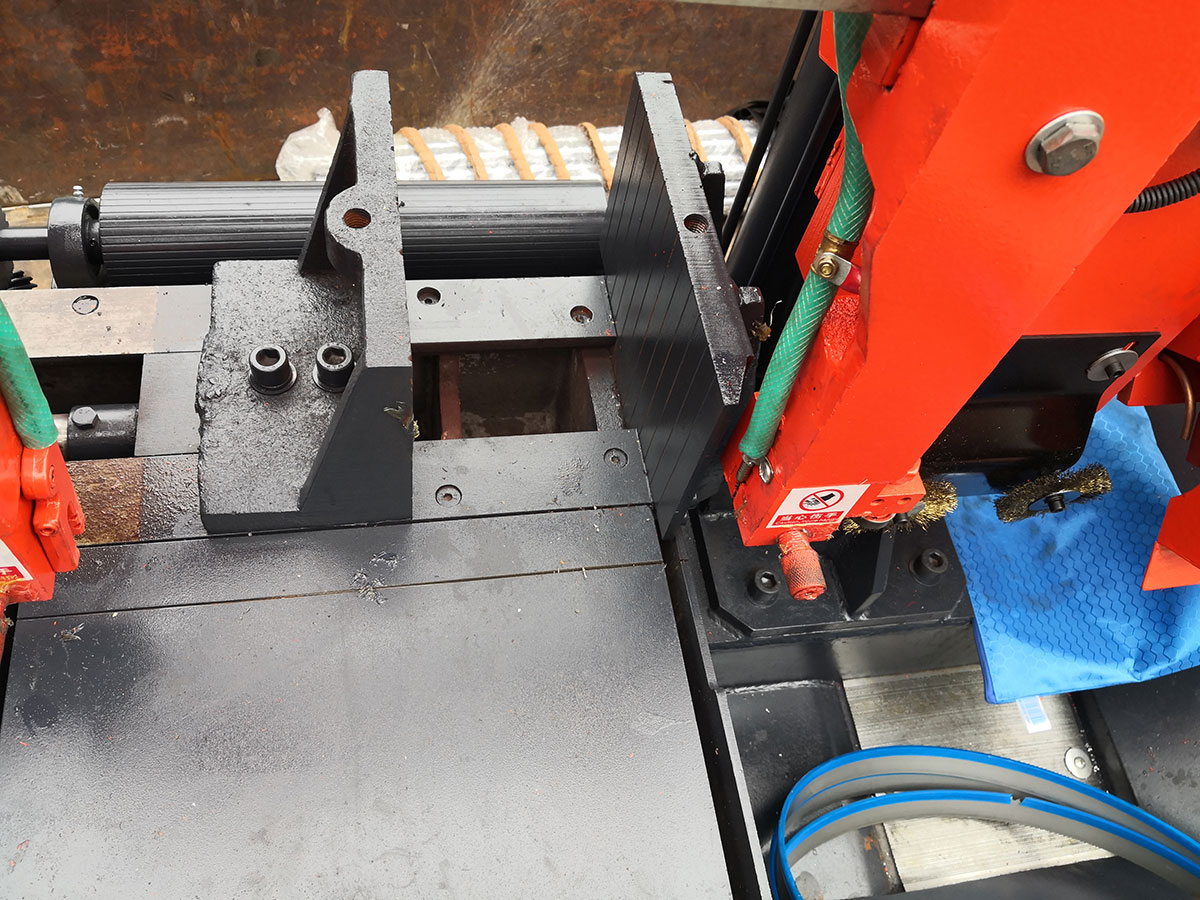

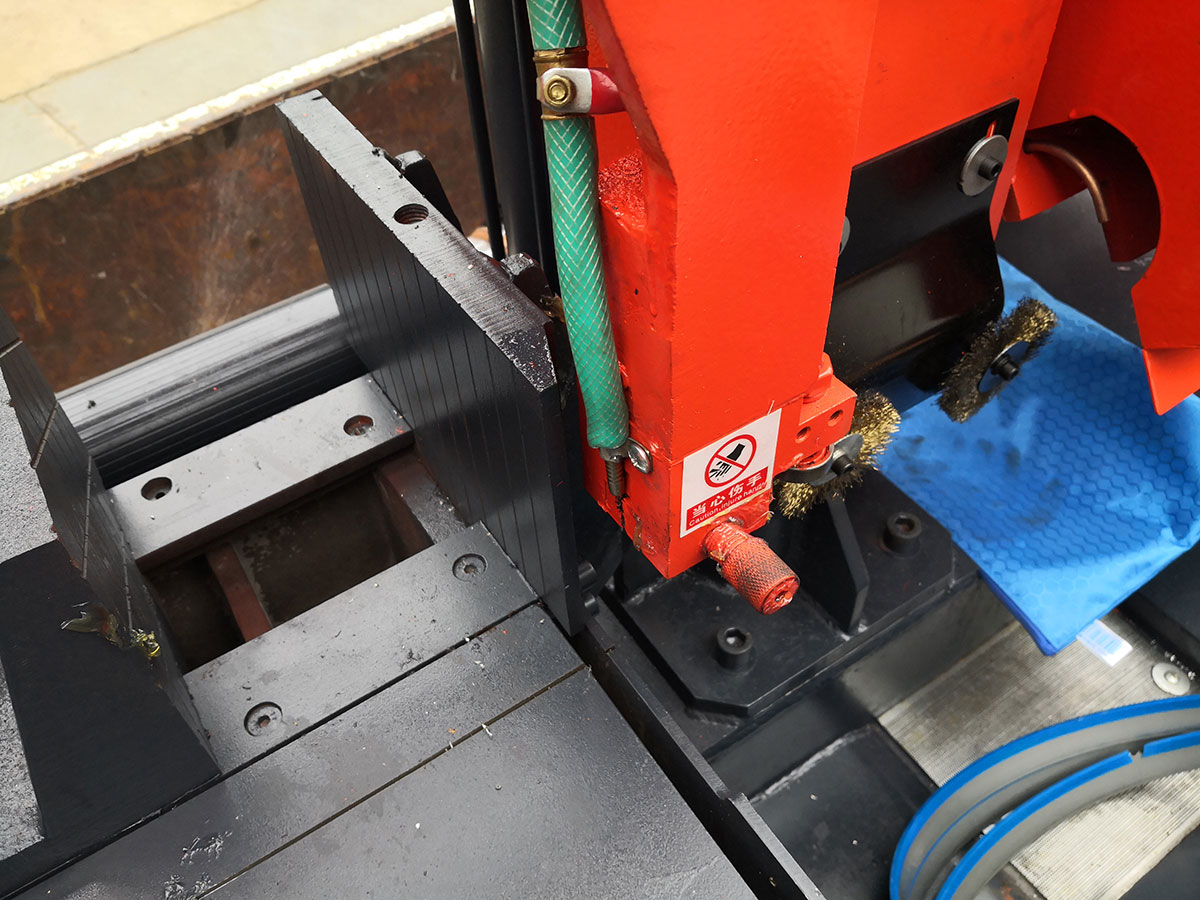

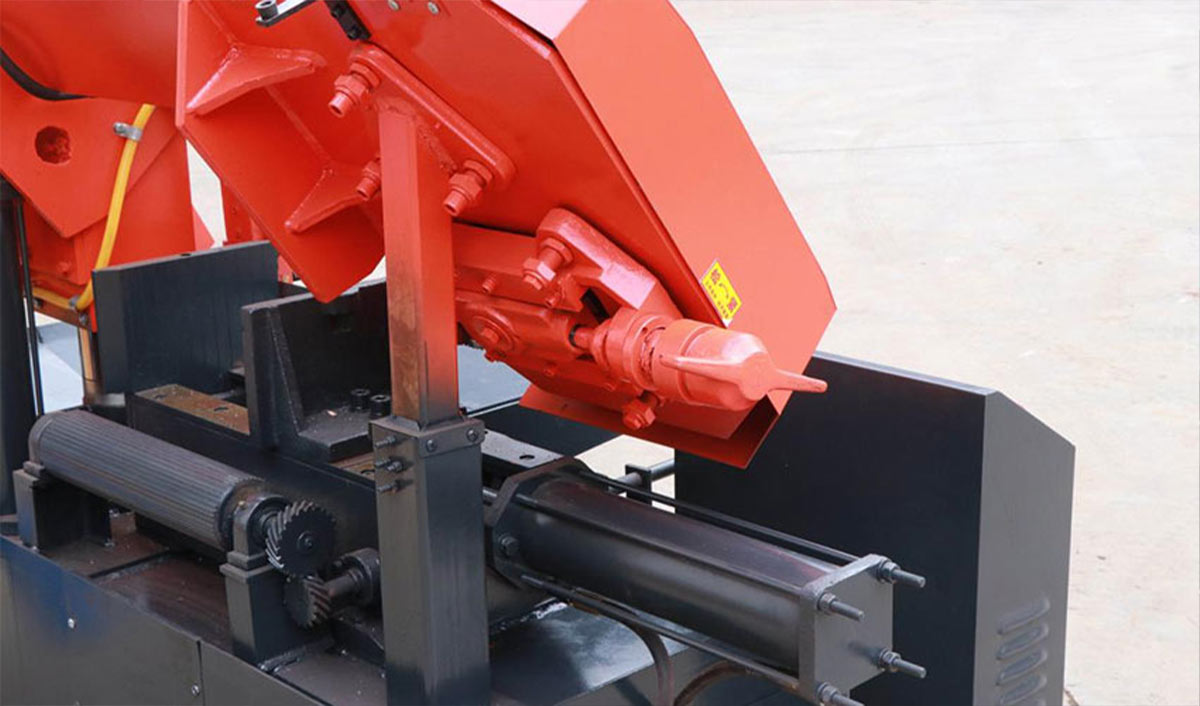

G4230 horizontal band sawing machine is a new generation of band sawing machine designed and developed by the company, featuring with double-column guide, cylinder lifting, reliable performance, and artistic appearance. The surface of the column is coated with hard chrome to prevent wear, ensure high prevision and improve the service life of the machine tool. With hydraulic lifting, stepless speed regulation, and self-set range, the good sawing conditions are easily satisfied. The machine tool adopts hydraulic clamping system for convenient operation. The saw blade adopts the bearings and adjustable tungsten steel guide to ensure sawing accuracy.

The sawing range of this sawing machine is 300*300mm. The machine is an ideal cutting equipment in large and medium – sized enterprise for energy saving to cut various soft and hard ferrous or non-ferrous metal materials after selecting appropriate parameters and adjusting different speeds.

II. Key Technical Parameters

| Sawing machine model | GB4230 |

| Cutting range (H × W) | 300×300 mm |

| Upper clamping range | 750×150 |

| Saw band spec. (length× width× thickness) | 3680×27×0.9 mm |

| Saw band speed belt speed regulation | 27、45、55、69、85 m/min |

| Feed speed | Hydraulic stepless speed regulation mm/min |

| Main motor power(kw) | 3.0 Kw |

| Hydraulic motor power(kw) | 0.75 Kw |

| Cooling motor power(kw) | 0.04 Kw |

| Vise clamping method | Manual |

| Outline dimensions of machine | 2100×1050×1550 mm |

| Machine weight | 960 KG |

III. Performance and Configuration

1. The main and auxiliary double-column structure is used with mature technology and high precision, and the surface is plated with chrome to provide artistic appearance and anti-rust.

2. The hydraulic cylinder can work automatically to realize the clamping action, which is easily operated and labor-saving.

3. The main cutting speed of the saw band can be adjusted at three levels, providing simple operation, reliable use, and prolonged service life of the saw blade.

4. The key original hydraulic components and seals adopt the original hydraulic parts, featuring with long service life, good reliability and long trouble-free time.

5. The key original electrical components adopt the original parts from CHINT Group, Tengen, AMB and Taiwan Delta, featuring with long service life, good reliability and long trouble-free time.

6. The saw blade has a flexible steel brush, which can fully remove iron chips in time from the tooth part of the saw blade and prolong the service life of the saw blade.

7. The 34×1.4 saw band is selected to enhance the sawing capacity of alloy materials with high hardness, greatly reduce the band breakage during sawing and improve the quality of use.

IV. Technology and Quality

1. The new product that fully meets the standards and passes the strict inspection are provide.

2. The main structures (such as machine bed and saw frame) are subject to the surface sandblasting and vibration aging treatment (internal stress removal process) to ensure the elimination of internal stress and enhance surface adhesion.

3. The German process technology and management technology are adopted for the quality control of the entire process.

4. The main drive worm adopts the following processes: blanking → rough machining → quenching and tempering → fine processing → surface quenching → gear teeth grinding processes.

V. GD4265 Technical Standards

This machine tool complies with the following standards:

JB/T4318.3-2002 Horizontal band sawing machine – Testing of the accuracy

JB/T4318.4 – 2002 Horizontal band sawing machine – Technical conditions

JB16454 – 1996 Sawing machines for metal cutting – Safeguarding specifications

Home

Home Consult

Consult Products

Products